With the growth of various industries and the increasing emphasis on effective product packaging, considerable attention has been focused on the development of packaging nylons and films. Among the different types of stretch films available, stretch pallet wrap stands out as the most suitable option for packaging a wide range of goods and products across various sectors.

Stretch pallet wrap is crafted from linear low-density polyethylene (LLDPE), which provides exceptional elasticity, making it highly effective for wrapping around objects. This type of film is primarily used for packaging and securing products on pallets, ensuring stability during storage and transportation. Its high resistance to moisture and chemicals further enhances its suitability for protecting goods.

The affordability of stretch pallet wrap has contributed to its widespread use in numerous industries. In the following sections, we will delve into the various aspects of stretch pallet wrap, allowing you to thoroughly evaluate its features and benefits before making a purchase.

Types of Stretch Pallet Wrap

• Manual stretch wrap: Often referred to as cellophane, this type of nylon has numerous everyday applications. Manual stretch pallet wrap is available in various thicknesses and typically comes in a transparent form.

• Power wrap: Known for its high strength and elasticity, power wrap is used for packaging and securing various products in warehouses and during transportation. Its thickness and durability make it suitable for a range of applications.

• Super power stretch: By enhancing the nylon formulation, scientists have managed to increase the stretch capacity of the film by up to twice as much. This type of wrap, known as super power stretch, is popular for packaging profiles, pipes and fittings, tissue, cartons, and other products.

• Silage stretch wrap: This specialized stretch wrap is designed for packaging fodder, animal feed, and agricultural products. It plays a crucial role in agriculture and horticulture, helping to protect and preserve these items.

Advantages of Using Stretch Pallet Wrap

• Affordable price: One of the key advantages of stretch pallet wrap is its cost-effectiveness. It is generally more affordable compared to other types of packaging. Additionally, the equipment required for applying stretch pallet wrap is less expensive than that needed for other packaging methods.

• Protection of goods and products: Stretch pallet wrap has a long history of use for protecting products from moisture and dust. It offers high safety properties, and UV-resistant versions of the film can be used to shield goods from sunlight.

• Compatibility with various goods: Stretch pallet wrap is highly versatile and can be used for a wide range of products. Its adaptability makes it suitable for almost any type of goods, enhancing its appeal across various industries.

Applications and Uses of Stretch Pallet Wrap

| Feature | Description |

|---|---|

| Importance in Industry | Suitable for packaging and transporting various goods worldwide, protecting products from damage |

| Material and Physical Properties | Thin, transparent, high adhesion, protective as a wrap around goods |

| Applications | Packaging furniture, fabric balls, wallpaper, wooden frames, toys, car spare parts, glass containers, pipes and hoses, aluminum sheets, P.V.C sheets, construction equipment, carton production industries |

| Different Types | UV-resistant stretch, perforated, anti-static (anti-static), colored, etc. |

Features of Stretch Pallet Wrap Produced by Keyhan Plastic

This nylon is a variant of stretch film, which, while sharing several common features with other packaging films, possesses distinct characteristics that set it apart. Available in both colored and transparent options, stretch pallet wrap is distinguished by its high elastic strength and strong adhesion, which are crucial for securely holding objects. This type of wrap exhibits high resistance to impact and tearing, ensuring that products remain protected during handling and transportation.

The durability of stretch pallet wrap is closely linked to the quality of the raw materials used in its production. Higher-quality materials contribute to a more robust and reliable product. Typically, the 5-layer structure of stretch pallet wrap plays a significant role in enhancing its overall quality, providing additional strength and resilience to the wrap. This multi-layer construction is essential for achieving the desired level of performance and protection in various packaging applications.

Dimensions and Thickness of Stretch Pallet Wrap

A high-quality stretch pallet wrap is characterized by its thin and lightweight nature, yet it possesses exceptional tensile resistance. Among its desirable features are its high brightness and transparency, which enhance visibility and aesthetic appeal. It is advisable to avoid opaque and dark stretch films, as they may compromise the ability to see the packaged items clearly.

This stretch pallet wrap is versatile, suitable for both manual and machine use, and is available in a range of colors to meet various packaging needs. The film’s thickness ranges from 12 to 40 microns, and it is sold based on weight. One of its notable attributes is its high flexibility and tensile strength, exceeding 400 percent, which ensures it can stretch considerably without breaking. These qualities contribute to the film’s integrity and resistance, making it a popular choice in the packaging industry. Additionally, its reasonable price further drives its high demand among manufacturers and distributors.

Additives

This product can be enhanced with various additives, such as Anti-UV treatments, to improve its performance. The inner layers are treated with PLD glue, which provides strong adhesion and ensures that the wrap securely holds the packaged items. Additionally, the stretch film is designed to resist heat effectively and features anti-static properties, which help prevent dust accumulation on the wrap.

Customers can order this stretch pallet wrap in bulk and choose between two forms: matte and transparent. The matte finish offers a non-glare option, while the transparent version allows for clear visibility of the wrapped products. Both forms maintain the wrap’s high performance and protective qualities.

Weight of Stretch Pallet Wrap

The weight of stretch pallet wrap is tailored to meet the specific requirements of each customer. Clients can order the pallet wrap in a range of widths, from 5 to 15 meters, and choose a thickness between 12 to 40 microns. Generally, for a typical dimension of 1 meter by 1 meter, the average weight of stretch pallet wrap produced by Keyhan Plastic is approximately 1 kilogram. This flexibility in customization ensures that the product can be adapted to various packaging needs and applications.

Stretch Pallet Wrap Machine

The stretch pallet wrap machine comes in various models, each designed to facilitate the packaging process in a manner that simplifies transportation and minimizes the risk of damage during transit. Compared to manual devices, utilizing fully automatic or semi-automatic machines offers significant advantages in terms of efficiency and ease of use. Manual wrapping methods often require more manpower and may not be practical for wrapping large quantities of product alone.

There are several types of automatic and semi-automatic stretch wrapping machines available, including:

• Turntable stretch pallet machine

• Stretch pallet machine or portal stretch wrapping machine

• Ring stretch pallet or stretch wrapping machines

• Portal ring stretch pallet machines

• Other types of stretch wrapping machines

It’s important to note that each of these machines may have various subtypes, each tailored to specific wrapping needs and operational efficiencies. More detailed information about the different types of stretch pallet wrap machines can be found in dedicated articles on the subject.

Packaging Method with Stretch Pallet Wrap

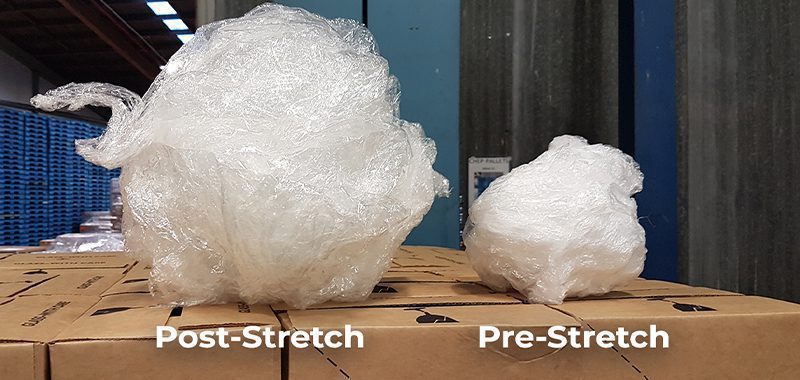

In the manual method of stretch pallet wrapping, the speed of work is notably slow, and the associated cost of manpower is relatively high. Stretch pallet packaging machines are designed to address these issues by significantly reducing waste and improving efficiency.

Semi-automatic machines often feature rotary packaging, where the load is placed on a rotating plate and wrapped with stretch pallet wrap film that moves vertically around it. This method enhances wrapping consistency and speeds up the process compared to manual methods.

Open packaging methods involve the load rotating on a stationary surface while being wrapped, whereas orbital packaging utilizes a moving film ring to wrap the load as it is fed through the machine.

Automatic packaging systems include conveyor belts and fully automated machines that handle cutting and sealing the stretch pallet wrap, further streamlining the packaging process.

For a visual demonstration of the packaging methods and to see Keyhan Plastic’s solutions in action, please watch the following short video prepared for you.

Production of Stretch Pallet Wrap

Stretch nylon comes in various models and is primarily available in matte or transparent forms. However, upon special request, colored stretch pallet wrap can also be produced. The typical thickness of this nylon ranges from 10 to 50 microns, with 24 microns being the most popular due to its balanced properties.

The tensile strength of the nylon increases with its thickness. It is crucial that each meter of pallet wrap nylon can stretch up to 10 meters, ensuring its effectiveness in securing and protecting goods.

Stretch pallet wrap is manufactured by numerous brands, and one of the most renowned in the industry is Keyhan Plastic.

Stretch Pallet Wrap Film Producer

Stretch pallet wrap film can be customized in terms of dimensions, color, and the addition of various compounds. Key additives include:

• UV Additive: Enhances resistance and extends the lifespan of the product by protecting it from ultraviolet light.

• Anti-Static Additive: Prevents dust attraction, keeping the wrapped items clean and free from dust buildup.

Keyhan Plastic Parsam Company, one of the largest producers of various stretch pallet wraps and other high-demand nylons, is committed to offering products with the highest quality and most reasonable prices. For inquiries or to purchase, please contact Keyhan Plastic experts for detailed information and assistance.

Daily Price Inquiry for Stretch Pallet Wrap

The price of stretch pallet wrap is highly cost-effective given its excellent material quality and functionality. However, the cost can fluctuate due to several factors, including:

• Custom Production: Different dimensions and custom specifications requested by customers can affect the price.

• Color Options: Colored stretch pallet wrap can be more expensive than standard transparent options.

• Additives: The inclusion of various additives, such as UV or anti-static, influences the overall cost.

• Weight and Number of Layers: The thickness and layering of the nylon impact pricing.

• Raw Material Price Instability: Fluctuations in the prices of raw materials, influenced by factors such as dollar rates and global market conditions, can cause price changes.

• Production Process: Variations in the manufacturing process may also affect the price.

The most significant factor affecting the price of stretch pallet wrap is often the fluctuation in raw material costs, which can change frequently due to global price shifts. For up-to-date pricing and to make a purchase, it is advisable to contact reputable manufacturing companies directly. You can call the numbers listed on the website for the latest information and to place an order.

Sale of Stretch Pallet Wrap

Stretch pallet wrap is available from many suppliers, but purchasing from a reputable manufacturer is crucial. Opting for low-quality nylon can lead to financial losses due to frequent replacements and inadequate performance. Ensuring you buy from a trusted source will save you from these issues and provide better value and reliability.

Purchase of Stretch Pallet Wrap at the Most Reasonable Price

Purchasing stretch pallet wrap is essential for various industries and manufacturers due to its effectiveness in packaging goods. This product offers a range of features and applications, making it suitable for protecting and securing items during storage and transportation. Stretch pallet wrap is known for its affordability, especially considering its high quality and functionality.

The wrap provides reliable protection against dust, moisture, and other environmental factors that could damage products. Its elasticity and strength ensure that goods are securely wrapped, reducing the risk of damage during handling and transport. The transparent film also allows for easy identification of packaged items.

The price of stretch pallet wrap varies due to fluctuations in raw material costs. Since the price is calculated per kilogram, and raw material prices change frequently, we cannot list a fixed price on our website. For the most accurate and up-to-date pricing information, please contact us directly. Our team can provide detailed information and assist with customizing your stretch pallet wrap to meet your specific needs.

To inquire about pricing, customization options, or to make a purchase, please use the contact numbers provided on this page. We are committed to offering high-quality stretch pallet wrap and ensuring excellent service throughout your purchasing process. Click on this link to buy quality stretch film.