Let’s start by examining stretch film and addressing what it is, along with its key characteristics. Stretch film, often referred to as stretch packaging, is primarily used for wrapping and securing products on pallets, ensuring they remain stable and protected during transport. This packaging material is usually made from polymeric substances, which provide the necessary flexibility and strength. The use of stretch film has rapidly become widespread across various industries, thanks to its cost-effectiveness and efficiency. One of the main reasons for its popularity is the affordable price, which makes it an economical choice for businesses looking to secure their goods. Before purchasing stretch film, it’s advisable to familiarize yourself with the different types and their specific applications to ensure you choose the right one for your needs. Understanding the various options available can help you make an informed decision that best suits your packaging requirements.

Purchase and Pricing of Keyhan Plastic Packaging Stretch Film

Before purchasing stretch nylon, it’s essential to become well-acquainted with several key points, such as the features, specifications, and pricing methods for packaging stretch films. Many producers and suppliers handle these packaging films based on their specific business needs. The demand for this type of packaging film is high due to its versatile applications in warehousing, transportation, product packaging, and freight purposes. Manufacturers across various industries purchase and store large quantities of packaging stretch films in their warehouses to meet their needs.

In some cases, the price of raw materials can fluctuate hourly, affecting the overall cost. Noavaran Keyhan Plastic Parsam Company, a leading manufacturer of various five-layer packaging stretch films, is prepared to customize your order according to your specified dimensions and features. For an accurate and up-to-date quote on packaging stretch film prices, you can contact us directly.

Now, let’s draw your attention to the continued features and specifications of Keyhan Plastic packaging stretch films. For more detailed information about stretch nylon, please refer to the relevant page on our website.

Packaging Stretch Film

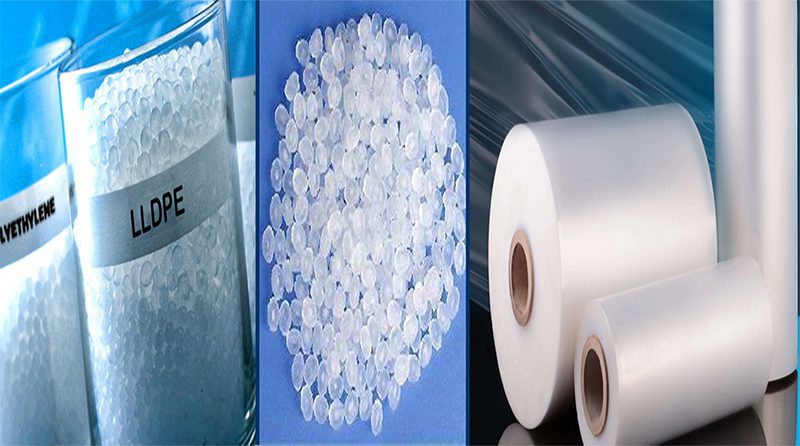

Stretch film is a highly elastic plastic film commonly made from linear low-density polyethylene (LLDPE) and is utilized for packaging purposes. In today’s commercial industry, these films are widely used to package a variety of goods. The primary factor in securing items is the high elastic strength and adhesion of the stretch film, which offers significant resistance to impact and tearing. Moreover, these films exhibit excellent resistance to moisture and chemicals, ensuring the protection of packaged goods. Stretch films are available in both colored and transparent options and are known for their lightweight properties.

Standards and Design

Plastic film is designed and manufactured following industry standards and guidelines to ensure quality and reliability. When it comes to protecting products or ensuring the safe transportation of goods, packaging stretches are an essential choice. The ease of use and durability of these films make them a practical solution for many applications. Different types of stretch films are available, each suited to specific needs and conditions. We will explore these variations in more detail in the following sections.

Types of Stretch Film

Packaging stretch films come in various types, each tailored for specific product packaging needs. For example:

Pallet Stretch

Used for packaging various products and goods; used for protection during transportation and keeping them new. Pallet stretch nylon has high resistance to moisture and chemicals.

Food Stretch

Used for packaging food products such as meat, chicken, mushrooms, etc., sold in various stores. Food stretch film is actually a protective cover for food. It doesn’t matter if the food is cold or hot; food stretch film can be used in any condition. This nylon, which is in the form of cellophane, prevents dust and insects from entering the food.

Forage Stretch

Used for packaging animal forage feed, which protects against spoilage and deterioration of animal feed, used by livestock farmers and farmers. More precisely, forage stretch is a type of polyethylene nylon that is usually multi-layered and is used to prevent direct sunlight and increase the shelf life of forage.

Industrial Stretch Film

Industrial stretch film is a type of polymer film made of polyethylene and is used for covering and packaging industrial and agricultural products. This film is transparent and glossy and has good flexibility. It is also moisture resistant and has negligible weight.

Pallet Stretch Film

Pallet stretch film is a type of polyethylene film used for wrapping and packaging products on wooden or plastic pallets. This film also has high gloss and good adhesion to the pallet surface.

Packaging stretch is also produced in various models, some of which include:

- UV stretch films

- Ventilated stretch films

- Anti-static stretch films

- Colored stretch films, etc.

Features of Keyhan Plastic Stretch Film

Keyhan Plastic stretch film has high adhesion capability and is suitable for any type and model of packaging. Also, the good flexibility of this product has made it one of the best-selling products in the market. It’s worth mentioning that Keyhan Plastic stretch film is 5-layer and while having an appropriate thickness, it is very light. The possibility of adding additives exists. Therefore, you can add your desired additives to the nylon in consultation with our colleagues. Another feature of this nylon is its brightness and transparency, which indicates the high quality of the product. Finally, it should be mentioned that this product is also produced in custom sizes and has reassured customers about the width and length of the product.

Advantages of Keyhan Plastic Packaging Stretch

The main advantages and distinguishing features of Keyhan Plastic stretch film compared to other productions:

- Reasonable price of packaging stretches

- Compatibility with various products

- Excellent adhesion

- Pre-sale and after-sale support and consultation for Keyhan Plastic packaging stretch films

- Being five-layered is one of the most important advantages of this packaging stretch film product.

Packaging stretch can be used by hand or through a packaging machine; the use of either of these methods depends on the size of the goods. If your goods are small, you can wrap it manually around it. But for larger items, if you have access to a stretch packaging machine, we recommend using this method, as the packaging process is carried out with confidence and requires less physical effort. You will become more familiar with the benefits of this packaging film below:

Stretch Film Producer

Keyhan Plastic is one of the largest and best producers of stretch film in Iran. This company is known for producing various types of high-quality plastic stretch films. Keyhan Plastic relies on research and development, updating machinery and equipment, using high-quality raw materials, and leveraging the knowledge and skills of specialized human resources to produce diverse and high-quality products. This company also considers the best prices for its products.

Specifications of Packaging Stretch Film

The layers of stretch film vary from 1 to 5 layers, and as the number of these layers increases, the quality of stretch films also improves. Packaging stretch rolls stick together when rolled on top of each other. This elasticity holds the load tight and firm. Stretch films do not need to use heat after packaging. Below are some other specifications of stretch film:

Adaptability of Packaging Stretch Film with Goods

Stretch films are produced in different widths, and since they have high elastic strength, they are adaptable to different surfaces with various sizes. On the other hand, transparent stretches give a more elegant appearance to the product, and customers can easily recognize their goods. This type of packaging usually does not get damaged even in the harshest conditions.

Mobility with Packaging Film

Packaging films are mainly used industrially and are used for packaging goods on pallets. This cover is wrapped around the goods several times and, in addition to facilitating the transportation process, helps reduce loading and moving time. This has multiplied the importance of this product.

Storage

Protecting goods against dust, moisture, and damage related to punctures and impacts is one of the most important reasons for the profitability of plastic packaging films. Since stretch films are designed to resist hardness, they are used for storing products in warehouses, shelves, garages, etc.

Low Weight of Stretch Films

The low weight of stretch films means that when wrapped around goods, it does not add much weight to them. While using packaging such as boxes adds more weight to the product. The main reason for the low weight of these films is the very thin thickness of the stretch film.

Excellent Adhesion of Stretch Film

Keyhan Plastic stretch film, with its excellent adhesion capability, is suitable for any type of packaging. Adhesion capability is one of the important features of this product, because for tight, orderly packaging, protection of goods, etc., it is necessary for the packaging nylon to adhere well to the product.

Economic Efficiency with Packaging Stretch

Packaging with stretch film is economical and is used entirely according to the needs of the goods. The use of rope, strap, and string, in addition to not having enough strength to hold the goods, does not protect it against atmospheric factors such as moisture, rain, dust, etc. These conditions can incur high costs for drivers or manufacturers.

Types of Stretch Film Packaging in the Market

If we ignore the classification of stretch films in terms of consumption, they can be divided into two types: manual and machine:

Manual Stretch Film

These types of films, as their name suggests, are used for manual packaging of products. Generally, products with small and medium dimensions are packaged using this method.

Machine Stretch Film

These types of films are also produced for packaging products with the help of special machines for this work. Generally, in heavy industries and food factories, these films are used for packaging products in large volumes and sizes. The device used for this purpose is called a stretch pallet wrapper, which is also known in the market as a cellophane wrapping machine. Also you can see other types of stretch nylon such as food stretch wrap and stretch pallet wrap in the related web pages.

Applications of Stretch Film

One of the common applications of stretch film is in pallet packaging. In moving pallets for loading onto ships and airplanes for exporting manufactured products, using stretch film is the best option. Other applications of packaging stretch film include food packaging and forage packaging. There is a variety of packaging stretches for any type of product. It has also been widely used and applied for any type of production in various industries.

If you are a product manufacturer and don’t know what type of stretch film is suitable for your products, and don’t know in what dimensions and sizes to purchase your packaging stretch, we recommend that you contact the numbers on this page and explain your work conditions to our colleagues; so that our colleagues can explain to you which packaging stretch film is the most cost-effective for your business.

With the production of various types of stretch film, a great transformation has been created in the packaging industry. The material of stretch films differs from each other, a major part of this difference is made according to the customer’s order request. The price of stretch film varies depending on the type of each product, and each type of stretch film differs from each other depending on the sizes and additives that are added and made to it. Purchasing stretch film, especially some types of it, is among the items that are usually used daily in many businesses so that people can more easily package and transfer their goods using packaging films. Packaging stretch rolls are usually purchased in high tonnage.

Components of Stretch Film

The raw material for stretch film is linear low-density polyethylene or LLDPE, which is made by combining it with other polymers such as butene, hexene, and octene. The use of hexene and octene in the production process of packaging stretch film products, due to the higher carbon content in them, increases its strength. The tensile strength of many produced stretches is up to six times their normal state.

Usually, when using them, they are stretched between two to four times their normal state. Of course, due to the elastic recovery property that exists in the producing polymer, the strength of these nylons is increased. If these films are to be used for packaging food that is in direct contact with it, care should be taken to use polymeric materials that do not cause health problems when in contact with food.

Stretch Film Production Line

In the stretch film casting production line, coextrusion is performed in several basic stages. The main raw material of this project, i.e., linear polyethylene plastic granules with low specific weight, must be of good quality and tested according to the standards mentioned in the first chapter.

In a final summary, you became familiar with stretch film and its types, and you realized that before buying stretch film, you should pay attention to a series of points and features of packaging stretch rolls. More important than anything is the appropriate price of stretch film, which is very cost-effective considering the weight, dimensions, and quality of packaging films, and our ultimate goal is customer satisfaction. If you have any questions for quoting stretch films and any other information, you can contact the numbers on this page.

Can I use this stretch film for wrapping pallets in cold storage?

Absolutely! Our stretch films maintain excellent cling and flexibility even at low temperatures, perfect for cold storage use